Our Machines

מכונת AVN

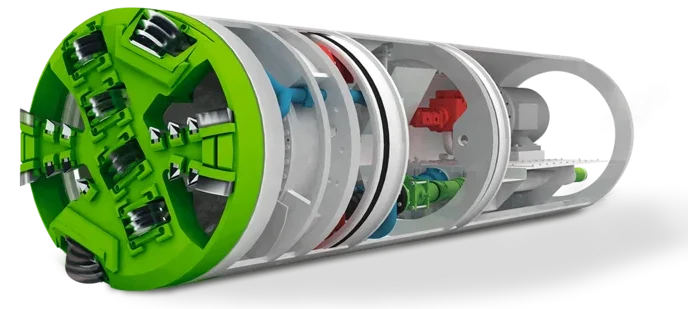

Herrenknecht AVN machines (Automatic Tunnelling Machine Wet) are Slurry Pressure Shield systems, also known as Slurry Machines.

Equipped with a Cone Crusher, these machines excel in tunneling through non-man-entry diameters, ensuring safe and stable operation.

Slurry support at the tunnel face allows AVN machines to operate in all ground conditions—from silt and clay, through non-cohesive soils and gravel, to solid rock—using both Pipe Jacking and Segmental Lining methods.

Geology

· אדמה חולית

· אדמת חרסית

· קרקע סלעית

Diameter

· עד קוטר חיצוני (OD) של 4.8 מ׳

· דחיקת צינורות החל מ-DN250

· דיפון סגמנטים החל מ-DN3200

כמעט כל סוגי הקרקע ניתנים להתמודדות בטוחה באמצעות המכונה.

ראשי חיתוך לקרקעות רכות, קרקעות מעורבות וסלע: Herrenknecht מציעה את הפתרון המתאים לכל אתגר גאולוגי.

בקרקעות קוהסיביות, מערכות התזה שונות מונעות בהצלחה סתימות בתא החפירה.

Cutterhead Design Adapted to Ground Conditions

The soil ahead of the machine is removed via Full-Face Excavation using a cutterhead specifically adapted to anticipated ground conditions.

Soft & Mixed Ground: In soft soils and mixed geologies, standard or mixed cutterheads are used.

Hard Rock: For tunneling in stable rock, a dedicated rock cutterhead featuring disc cutters is installed.

Simultaneously, a tapered cone crusher within the excavation chamber crushes stones or obstacles to a grain size suitable for transport. The material then falls through sieve-like openings at the suction intake and is pumped out with the slurry via the slurry line.

Expandable Diameter

The excavation diameter can be flexibly increased within a certain range using an extension kit and a modified cutterhead.

Thus, especially in Pipe Jacking operations, the AVN machine allows for the execution of various diameters and the use of diverse pipe materials.

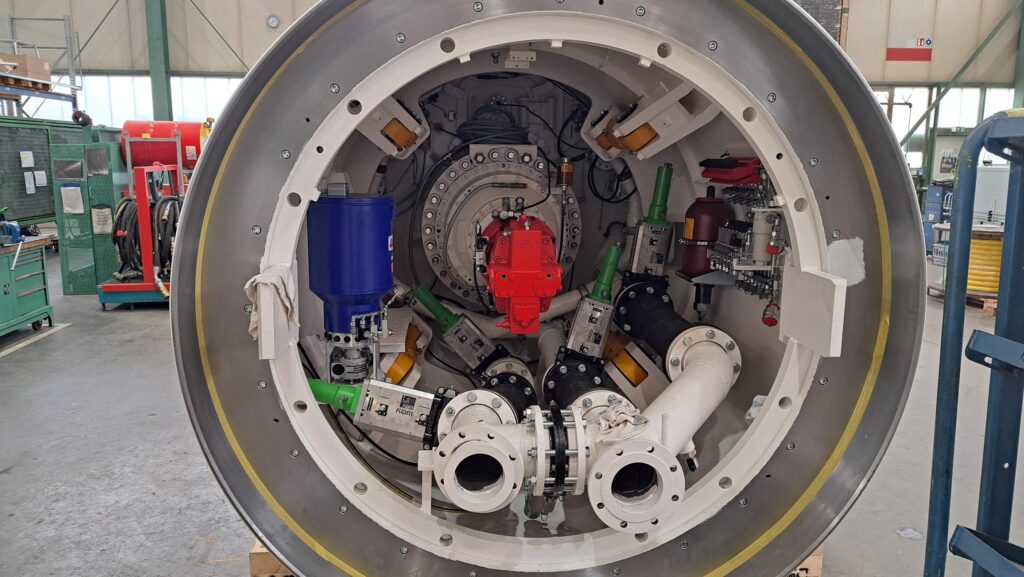

Jetting for Smooth Material Transport and High Advance Rates

Particularly in cohesive soils (like clay), keeping the cutterhead and crusher area free of blockages can be challenging. Based on years of global experience, Herrenknecht has developed dedicated jetting systems tailored to different soil types:

High-Pressure Nozzles: Located in the cone crusher, these inject additional water for cleaning, breaking down clay or loam, and preventing accumulation and clogging in the crusher area.

Medium-Pressure Jetting: Performed via bentonite injectors.

Changing the nozzle diameter allows for adjustment of slurry pressure, thereby optimizing material flow.

Long-Distance Pipe Jacking

AVN machines are frequently used for pipe jacking projects. The maximum jacking length depends on factors such as skin friction, available jacking force, and pipe diameter (DN).

Friction Reduction: Automatic lubrication systems reduce friction between the pipe skin and the ground by injecting bentonite into the annular gap.

Intermediate Jacking Stations (Interjacks): In man-entry diameter ranges, hydraulic intermediate jacking stations can be used. These stations are installed along the pipe string at intervals defined specifically for each project. Dividing the pipe string into separate sections reduces the required jacking force and distributes it efficiently.

Consequently, the distance between the launch shaft and the reception shaft can reach or even exceed 1,000 meters, depending on project conditions and the number of intermediate jacking stations.

במכונות AVN קיימת דלת נוספת מאחורי ראש החיתוך, המאפשרת גישה לחזית המנהרה.

Maximum Precision Even in Curves

Depending on project requirements and the selected lining method, various navigation systems are available for the control and guidance of AVN machines. For further information, please refer to the Navigation and Monitoring chapter.

מידע נוסף ניתן למצוא בפרק ניווט וניטור.

Access to the Tunnel Face

Accessible (man-entry) AVN machines can be equipped with a dedicated door allowing access to the tunnel face.

Obstacle Removal & Tool Changes: This access may be required for removing obstacles or replacing cutting tools.

Rear-Loading Tools: The cutting tools are designed to be replaced from the rear side. Tool replacement enables longer drive lengths, particularly when working in hard rock.

Safety: If necessary, personnel can safely enter the

pressurized area via a Personnel Airlock.

Tunneling Without a Reception Shaft (Blind Hole)

Blind Hole tunnels pose a unique challenge, especially in small, non-man-entry microtunneling diameters.

Since these tunnels terminate directly within the ground, conventional machine recovery is not possible.

The Solution: Retractable Cutterheads For this unique application, Herrenknecht developed special cutterheads with a folding mechanism. Upon reaching the required jacking length, the microtunneling machine can be retracted back to the launch shaft with the cutterhead folded back. The jacking pipes remain in the ground.

Pipe Arches: A common use for Blind Hole tunneling is the construction of Pipe Arches. Steel pipes are installed side-by-side in the ground to create a protective arch.

Excavation of the final tunnel diameter is then performed beneath this arch using mining methods. This method enables safe undercrossing of railway tracks and the construction of metro stations.

House Connections & Logistics: Another application includes installing house connections or performing

tunneling works in cases where the reception shaft

has not yet been completed due to logistical reasons.

מגוון גדלים רחב זמין אצלנו לשימוש

500 ⌀

600 ⌀

800 ⌀

1000 ⌀

1200 ⌀

1500 ⌀

1720 ⌀

2160 ⌀

2500 ⌀